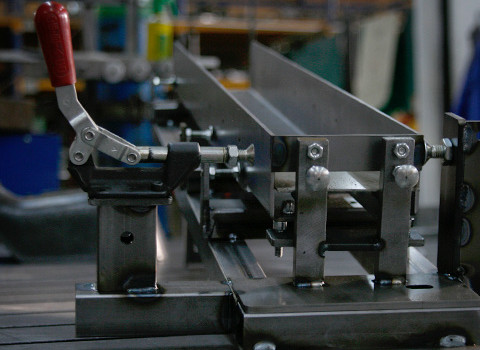

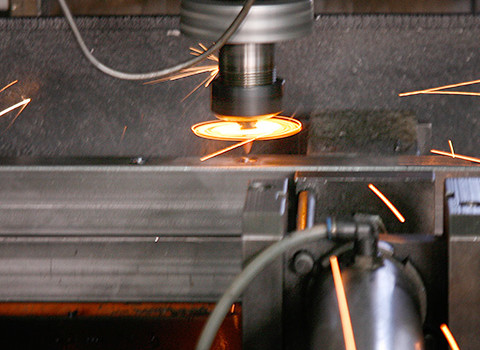

Quality

Quality With clearly defined processes and controls we ensure a constant quality. With permanent training and continuing education we continuously qualify our staff. We undergo a continuous certification according to the rules of DIN EN ISO 9001.