Complete and competent high-precision metalworking

From vision to full-scale manufacturing

Experience in metalworking

Innovative turnkey solutions with efficient production strategies

With over 60 years of experience, our name stands for innovation and expertise in metalworking. Our aim is to transform your ideas into marketable products using advanced technology and efficient production processes. We combine state-of-the-art machines and a high degree of automation with our expertise in metal. Benefit from outstanding turnkey solutions from a single source.

As experts in sheet metal and tube processing as well as metal cutting and welding with lasers, we design our production processes according to your needs, laying the foundation for a long-term partnership and your continued success.

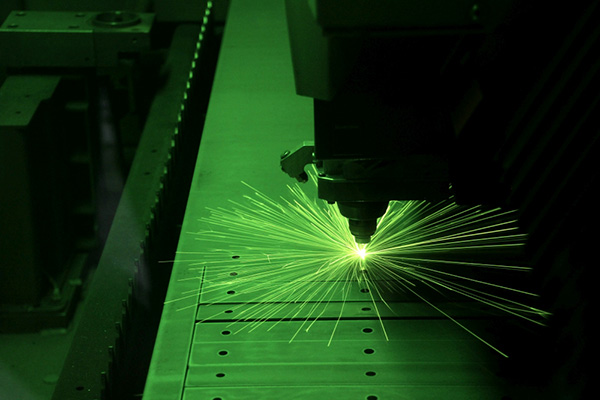

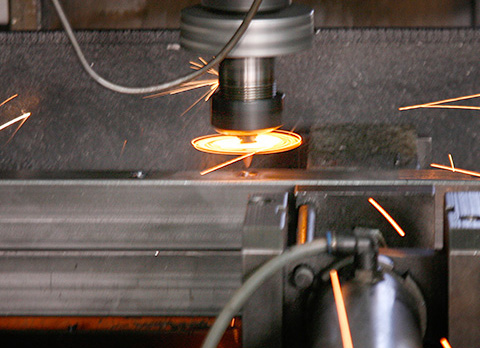

With us, you can experience the application possibilities of state-of-the-art laser technology in action. Whether it is laser cutting of sheet metal and tubes, laser drilling, laser engraving or laser welding, we can significantly improve the quality in terms of accuracy, surface and productivity with these technologies.

Competent project partner

We transfer your ideas into finished products. With our design-to-cost approach, we work together with you to optimize material and production processes for maximum efficiency and quality. We offer everything from a single source – from development and design to full-scale manufacturing.

Comprehensive turnkey solutions

Our wide range of manufacturing processes – tube lasers, CNC profile machining, welding, laser welding, powder coating, laser cutting and sheet metal bending – guarantee cost-efficient and production-optimized metal components.

Innovative metal processing at the highest speeds

The machines we use are the fastest and most precise in their class. Throughout our company’s history, we have always pioneered the use of state-of-the-art and innovative technologies in production for the benefit of our customers.

Over 60 years of experience in the full-scale manufacturing of complex metal parts

For over 60 years, we have stood for expertise and innovation in metal processing, particularly in sheet metal and tube processing using laser technology. At Metallbau Nick, we understand that every project must be considered holistically before it matures into full-scale manufacturing. That is why we work closely with you to develop the optimum solution for your specific requirements. Our aim is to achieve significant cost benefits for our customers through efficient full-scale manufacturing, especially for complex components for industrial applications. Our knowledgeable team of highly qualified experts realizes your visions with our large selection of production processes to manufacture medium to large batch size productions.

We strive for a growing and long-lasting partnership with our customers in every project, based on long-term full-scale manufacturing, leading to mutual growth and sustainable success through stability, increased efficiency and a deep mutual understanding.

With a team of over 60 qualified professionals, best-in-class machinery and a high degree of automation across all manufacturing processes, we support you from the initial idea to full-scale manufacturing. Our comprehensive vertical range of manufacturing capabilities enables us to respond flexibly to the specific requirements of metal parts and develop holistic solutions to guarantee efficient, future-proof full-scale manufacturing. Benefit from low transport costs, fast response times and optimized process chains – all from a single source and a single point of contact.

We develop and produce a wide variety of components for machines, covers, housings and other sheet metal and tube components for our customers, up to fully assembled modules. These can be delivered just in sequence to a production line and installed directly there. Even complex welded assemblies are no problem for us.

Our technology

Product development

Our expertise is transforming our customers’ ideas into real products, from the initial sketch to full-scale manufacturing. We place particular emphasis on optimizing the product for production. Thanks to the many years of experience of our employees, we can achieve major improvements together with our customers and decisively develop the design-to-cost principle.

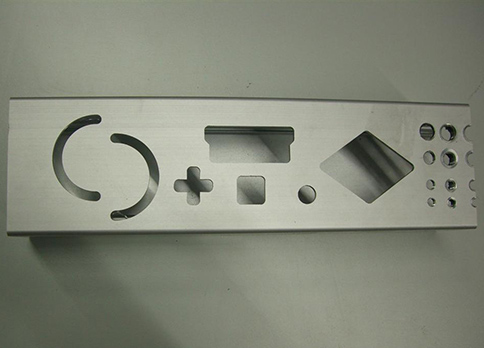

Sheet metal processing - ultra-modern and automated

In the world of metalworking, Metallbau Nick sets new standards with state-of-the-art CNC sheet metal processing. Our machinery, including flatbed lasers, fully automated bending and CNC press brakes, enables us to meet a wide range of sheet metal processing requirements with the highest quality. Whether it’s complex shapes or cuts, our fully automated bending centers and various forming and processing machines are designed to serve your specific needs efficiently and effectively.

This area has machines for most sheet metal processing operations. Our high-speed laser cutting machine achieves travel speeds of up to 170m/min and uses a 6kW laser to cut steel, stainless steel, aluminum and copper up to a thickness of 15mm, depending on the material. At the same time, the fiber laser technology used has significantly reduced energy consumption.

When bending, we can form the laser-cut sheets up to a length of 3000mm with a pressing force of 1500kN. Our high degree of automation allows us to manufacture around the clock using unmanned shifts.

Tube laser cutting - expertise meets flexibility

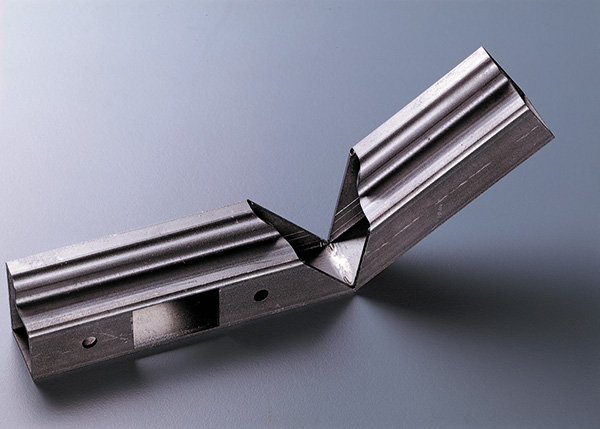

Modern tube laser technology opens the door to unimagined design possibilities, such as positioning aids for welding, puzzle joints, folding cuts and much more. Our advanced tube laser systems enable impressive flexibility in processing. No matter how complex or challenging – we set new standards in productivity and precision. With our laser systems and the ability to process a wide range of tube profiles, we are perfectly equipped to meet your specific requirements.

Modern tube laser technology makes it possible to cut/cut out, drill holes, connections and other features in a single operation at maximum speed. Round and rectangular tubes and many other geometries can be processed, up to a maximum length of 6,500 mm and tube dimensions of up to 150 mm enveloping circle. With the help of laser power of up to 2.5 kW, we cut effortlessly through steel tubes up to 8 mm thick.

Metallbau Nick’s strengths lie in the production of a wide variety of laser-cut tube parts, including advising customers on cost reduction, technical design and simplification of components. For example, if you look at a foulding cut, the welded component can be produced in an average of 49% less time. With an average workpiece mix, this leads to a reduction in manufacturing costs of around 31%.

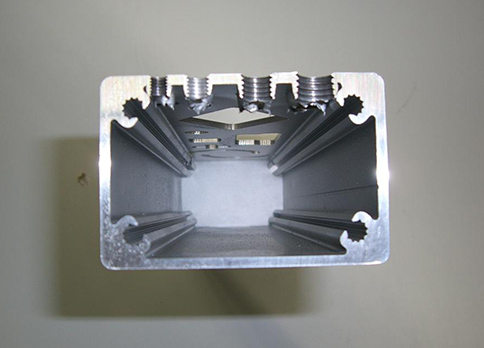

Profile machining - Machining of profiles and tubes up to 6 meters in length

We can also use our three machining centers, which are equipped with automatic tool changers. They are able to efficiently process a wide range of aluminum and steel profiles. Our systems enable a processing length of up to 6,000 mm and are ideal for milling and drilling work. We also offer flow drilling and thread forming. This ensures a standard-compliant screw-in depth for screws, even in thin-walled tubes.

Welding - component joining in perfection

Metallbau Nick combines know-how with state-of-the-art technology to produce cost-optimized batches of welded assemblies according to your requirements. Our welding expertise includes both manual welding stations and efficient robot welding for higher quantities. This is supplemented by the option of spot welding.

The MIG/MAG and TIG welding processes are available. These can be applied manually by our experienced and certified welders or by our robot welding systems. Our highly qualified welders are regularly certified in accordance with ISO 9606-1.

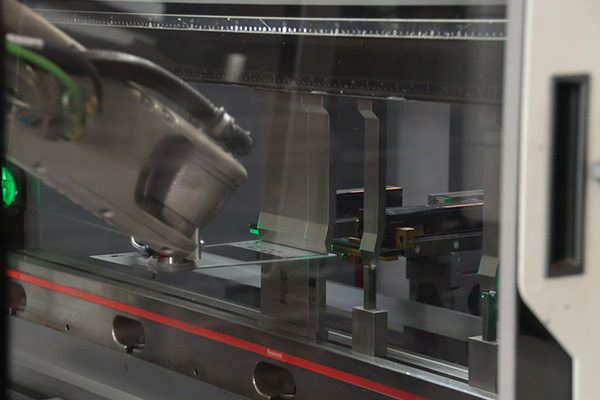

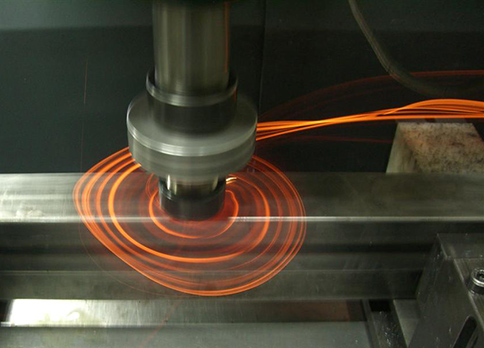

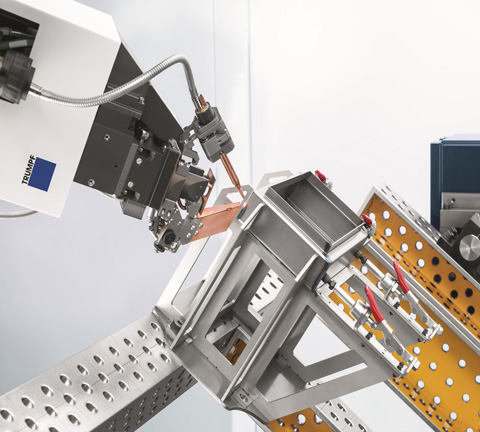

Laser welding - excellence in every seam

We rely on innovative laser welding to achieve deep, stable and smooth seams. This technology makes it possible to weld almost all materials, such as aluminum, stainless steel or structural steel, flexibly and with virtually no distortion. Our laser welding systems produce high-precision components both with and without wire feeding using a 6-axis robot and a laser power of 4kW. Discover the efficiency and quality of our laser welding in action (source videos & images: © Trumpf):

Laser welding uses the laser beam to join metallic components together. The high energy density produces connections with very high strength and virtually no distortion. The robot’s accuracy guarantees consistent, visually appealing welded seams for all common materials.

Grinding - Highest surface quality for the optimum finish

Depending on customer requirements, the components can be further processed on our sanding machines before coating. Sanding with horizontal and vertical belt machines enables an optimum finish. This is especially important as many of our customers are looking for a particularly aesthetic appearance of the component.

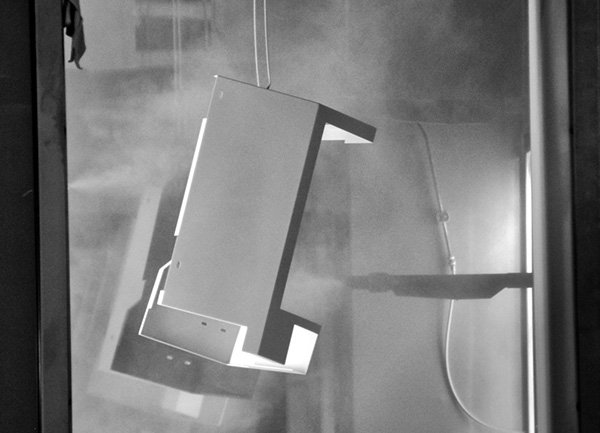

Powder coating - Durability and aesthetics with low environmental impact

We provide you with high-quality powder coating services that not only protect your metal parts from corrosion but also enhance their appearance. Our in-house powder coating facility is equipped with the latest technology, including a continuous line with pre-treatment and three changable powder booths, two of which enable automatic coating. This advanced technology guarantees a uniform and durable coating for a wide range of applications. For large series, we offer customized solutions to meet your specific requirements.

We have been using this environmentally friendly surface coating process since the 1970s. Components up to 2,800 mm in length can be coated in our powder coating facility in almost any color, even with different color effects, according to customer requirements.

Order picking and logistics

The individual parts manufactured by us and other purchased parts can be joined together into complete assemblies or even finished components. All important quality requirements are checked and documented. Your product leaves our company either pre-commissioned for further processing or fully packaged. Additional purchased parts, documentation etc. can also be packed. Environmentally friendly packaging is important for us; where possible, we do not use disposable packaging at all.

Our quality promise to you

At Metallbau Nick, quality is not just a promise, but our company’s heartbeat. We rely on clearly defined processes and strict controls to ensure the consistently high quality of our products and services. Our employees are our most valuable asset and through continuous training and further education we ensure that they always meet the highest standards in metalworking and laser processing.

Our quality management is certified according to DIN EN ISO 9001:2015, underlining our commitment to excellence and continuous improvement. This certification is a testament to our uncompromising quality assurance and our commitment to exceeding our customers’ expectations in every project.

Metalworking for a wide range of industries

Office furniture and special technical furniture

For special technical furniture, we produce robust metal components that combine functionality and design. Our manufacturing solutions range from specialized pieces of furniture to complex frames developed for specific technical applications. We work closely with our customers to develop products that combine economy and durability in high-volume orders. For the office furniture industry, we develop and manufacture metal components that guarantee ecological and economical production. With many years of expertise and close cooperation with our customers, we optimize material and manufacturing processes for efficient full-scale manufacturing. With comprehensive vertical integration and innovative processes, we create components for everything from elegant desks to functional office systems that meet modern workplace requirements.

For furniture and frame construction, we develop stable, elegant and low-welded seam frame constructions. Our metal components are characterized by great stability and durability.

Laboratory and medical technology

Our expertise includes the production of components for medical devices and laboratory equipment. We manufacture precise metal components for laboratory and medical technology that meet the high quality and safety requirements of these industries. By developing efficient manufacturing processes, each component is optimized for cost-efficient full-scale manufacturing.

Display/shop fitting

In display and shopfitting, we develop metal components for attractive and functional promotional shelves, robust shopfitting elements and elegant display structures that are suitable for full-scale manufacturing. Our production is geared towards efficient manufacturing and scalability in order to meet market requirements. Our metal parts can be used in a variety of ways, e.g. in promotional shelves that serve as product carriers and presentation areas as an attractive and stable solution for every trade fair and point of sale.

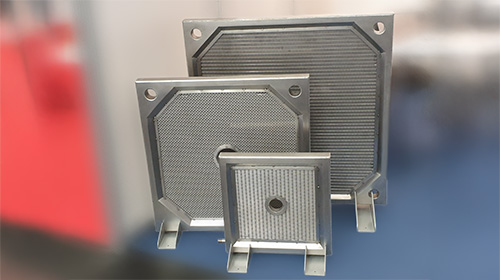

Filtration - Solid-liquid separation

We offer you a new generation of lightweight stainless steel recessed chamber filter plates for industrial solid-liquid separation in filter presses. In pressure filtration, the limits of what is feasible can be significantly extended with these products. Filtration processes that were previously not feasible can now be realized with existing system technology. The stainless steel filter plate offers a wide range of solutions for demanding filtration tasks. The outstanding properties of stainless steel, such as excellent strength, chemical resistance, food safety and high temperature stability, come into account here.

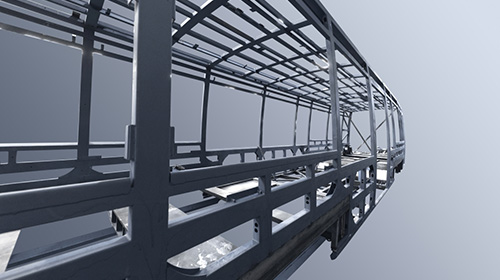

Vehicle parts

In vehicle construction, we concentrate on the production of metal components and assemblies for medium and large batch sizes. Through joint development with our customers and our design-to-cost approach, we ensure that our manufacturing solutions are both cost-efficient and tailored to the specific requirements of the industry. Customers benefit from us as a central point of contact for the entire process chain, according to the one-face-to-the-customer principle. We create kits of parts for frame structures from profiles with different geometries, including labeling and sorting, to ensure easy assembly and positioning in the subsequent production process.

Electric mobility and logistics solutions

We offer innovative metal solutions for the growing mobility market. The solutions range from customer-specific charging stations for electric bike batteries to components for wall boxes and complete sheet metal parts for entire charging stations. From design to production, we support the development of sustainable charging stations, mobile racks for hand scanners or housings for batteries with robust and ergonomic components. In addition, our metal constructions improve the user-friendliness of the charging stations. They offer compatibility with various models and can be easily integrated into existing infrastructures.

Let us discuss your project!

Rely on our expertise in metalworking.

Contact us today to make your project a reality!

Together for success: your visions for cost-efficient full-scale manufacturing

In our collaboration with you, we focus on a strategic approach that puts your needs first. We see each project as part of a larger system, and our focus is on achieving the maximum economic benefit for you through efficient full-scale manufacturing. We achieve this by working closely with you right from the initial idea. From the first contact to the production of the final product, we work closely with each of our customers and strive to deliver marketable and cost-effective solutions that are precisely tailored to the product requirements. Our extensive expertise in metal processing and our high level of vertical integration enable us to work with you to develop components that are both technically mature and optimized for full-scale manufacturing.

By combining your product expertise with our manufacturing know-how, we can achieve excellent results together.

Broad vertical range of manufacture with a high degree of automation

We are proud of our modern machinery, which includes innovative metalworking technologies and has a very high degree of automation. With automated bending, laser processing and powder coating, we can react efficiently and flexibly to the diverse requirements of our customers. Our production spectrum ranges from laser processing of sheet metal and tubes to welded assemblies and powder-coated components. We ensure the quality of our products and services by continuously investing in the latest technologies. This technological excellence, combined with our drive for constant innovation, enables us to push the boundaries of what is possible and develop complete solutions for our customers.

We transform your visions into marketable successes.

Contact us for quality and efficiency

With our experienced team and the latest technologies, we offer complete metal processing solutions for efficient full-scale manufacturing. Contact us today and let us advise you on how we can integrate efficiency and quality into your next project.

Metallbau Nick GmbH

Industriestraße 16

68623 Lampertheim

Germany

Tel.: +49 6206 9437-0

Fax: +49 6206 58335